Mail Us: [email protected]

Call For Us: +86-18742465373

Did you know about the importance of getting fresh and clean air to breathe for both man and machine? There are a lot of things that can make air in places like factories, warehouses and workshops dirty. All of these things like dust, smoke, noxious vapors and other chemicals. These will potentially damage our health and in addition, ruin the equipment we use. That's where industrial ventilation fans can come to the rescue.

Basically, industrial ventilation fans are large machines which operate in a manner akin to giant vacuums. They extract dirty air from inside the building, replacing it with clean fresh air form outside. They are usually mounted on walls, ceilings or roofs and connected to ducts that capture the pollutants from the air. Industrial ventilation fans help to remove old, stagnant air and bring in fresh clean air helping a lot on the improvement of indoor quality.. This creates a safer working environment for all.

It is very essential to select the correct industrial ventilation fan for you which will work flawlessly and safely. To begin with, you have to decide how much air mass flow are you trying to move around. This factor is to do with how big the room is; what kind of contaminants are in the air, for any safety regulations which need following depending on who will be working where and when.

Second you need to choose fan style which suits your requirement. There are various kinds of fans, including vaneaxial and centrifugal. These kinds have their own specific applications and behavior. Axial fans: These blow air straight (like desktop devices)Centrifugal Fans : These blow air sideways.

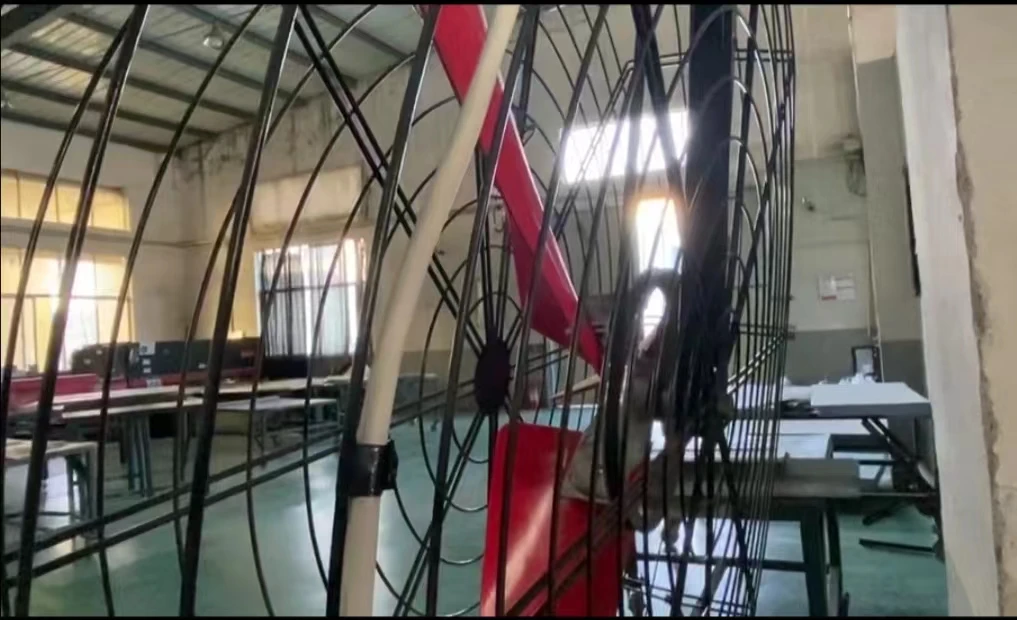

The next step is to compare different models of fans to see which motor is stronger, which one to regulate and which filters or replacements the fan has. Finally, one needs to think about the costs and benefits. It is essential to know that purchasing a good industrial ventilation fan means saving on energy bills, expensive repairs, and, which is the most important, your employees’ safety. Benefits of Energy-Efficient Industrial Ventilation Fans. Does it seem impossible that a fan can be super energy-efficient? However, some industrial ventilation fans consume a lot of energy, and thus it is crucial to have energy-efficient models. Energy-efficient fans are designed to have lower power consumption while maintaining good air redistribution quality. With these fans, you can save much money on power bills, as less power is consumed, which also helps save the planet. Different Types of Industrial Ventilation Fans. Industrial ventilation fans come in varying sizes and shapes and serve for several purposes. Ventilation fans are often axial or centrifugal fans and more: Axial fans. Axial fans look like a propeller and directly push air away. These are great for cooling and ventilating large spaces, making them ideal for agricultural industries and vast warehouses. Centrifugal fans. centrifugal fans have curved blades and directly divert air westward. They are usually found in small rooms of higher pressures such as air condition and processing dust. Manufacturing and food-processing industries frequently use them.

Poor Air Quality in Dangers of a Industrial Work Place Workers can face a lot of health hazards in dangerous gases and pollutants. Industrial ventilation fans serve as a safety measure in that they extract these toxic gases upon occurrence, and keep the workers safe. Hence, workers are not at the risk of contamination from high concentrations of hazardous substances that can cause severe health problems.

These fans not only eliminate dangerous gases from the building, but also prevent other problems such as heat, humidity and bad odor, etc. Industrial ventilation fans will help bring in clean air so that it creates a good and comfortable work environment. This helps everyone feel good and therefore work harder thus more productively.

FJDIAMOND has a total area of 50,000 square metres, featuring 160 production machines, 400 employees, multiple production lines, professional testing labs, and 30 years of experience in production. The company has achieved ISO9001 Quality Management System certification, and can fulfill the needs of its customers factory inspection.

Strict quality industrial ventilation fan, focused training for key positions, fixed staff and fixed positions Fixed quality inspections for each team, key areas of process with quality control of the process; steady supplier suppliers with full-time quality control personnel to manage raw material suppliers and to conduct regular inspections.

The full-time industrial ventilation fan is responsible for fast and timely response This will allow clients to successfully complete the service of the terminal market at a high speed and remove the concerns of the customers Our service system is flawless throughout the world

A strong R and D team with years working experience in production, will make products customized to meet the customer's specifications; extremely energy efficient, the industrial ventilation fan is of top quality energy consumption IE5 with a focus on product specifications and a wide range of customer groups as a basis, allows us to understand the needs of end customers The real requirements.